-

Truckar & ProdukterTruckar & Produkter

Startsida | Jungheinrich Sverige

-

Truckar - Alla truckmodeller

Truckar - Alla truckmodeller

Truckar & Produkter

- Pallyftare | Handtruckar

- Låglyftare | Ledtruckar

-

Ledstaplare

Ledstaplare

Truckar - Alla truckmodeller

- Ledstaplare | Alla modeller > Översikt

- Handstaplare | Manuell staplare > Arbetsbord

- Ledstaplare | Instegsmodeller

- Kompakta, underhållsfri ledstaplare för trånga utrymmen

- Staplare med bredvidgående förare > för korta transporter

- Ståstaplare / Åkstaplare > för medellånga transporter

- Sittstaplare > för längre transporter

- Dubbelstaplare > För effektiv lastning och lossning

-

Plocktruckar

- Skjutstativtruckar

- Smalgångstruckar

- Motviktstruckar

- Dragtruckar

- Specialtruckar > Skräddarsydda trucklösningar

- Truckar med explosionsskydd

- Släpvagnar

- Pallskyttlar

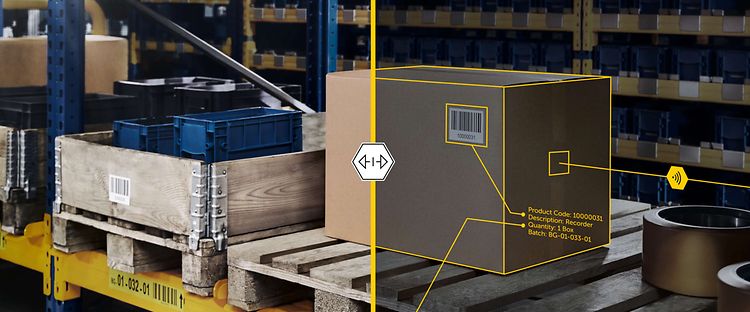

- Assistanssystem

- AntOn by Jungheinrich

-

Begagnade truckar

Begagnade truckar

Truckar & Produkter

-

Hyra truck

Hyra truck

Truckar & Produkter

- Sök hyrtruck direkt

- Hyra ledtruck / låglyftare

- Hyra ledstaplare

- Hyra dragtruck

- Hyra låglyftande plocktruck

- Hyra höglyftande plocktruck

- Hyra skjutstativtruck

- Hyra elektrisk motviktstruck / eltruck

- Hyra dieseltruck / gasoltruck

- Hyra truck över längre tid

- Hyra hela truckflottan > Rental Fleet Management

- Finansiering

-

Assistanssystem

Truckar & Produkter

-

Truckbatterier och laddningsteknik

Truckbatterier och laddningsteknik

Truckar & Produkter

-

Truckbatterier med effektiv energihantering

Truckbatterier med effektiv energihantering

Truckbatterier och laddningsteknik

-

Laddningsteknik

Laddningsteknik

Truckbatterier och laddningsteknik

- Truckmotorer

-

Truckbatterier med effektiv energihantering

-

Ställage och lagerinredningar

Ställage och lagerinredningar

Truckar & Produkter

-

Statisk pallagring

Statisk pallagring

Ställage och lagerinredningar

-

Dynamisk pallagring

Dynamisk pallagring

Ställage och lagerinredningar

-

Statisk smådelslagring

- Dynamisk smådelslagring

-

Lagring av långgods och lagerplattformar

Lagring av långgods och lagerplattformar

Ställage och lagerinredningar

-

Statisk pallagring

-

Industriell IT

-

Truckar - Alla truckmodeller

-

Automation & SystemAutomation & System

Startsida | Jungheinrich Sverige

-

Lageroptimering & Rådgivning

Automation & System

-

Materialflödesanalys

Automation & System

-

Automatiseringsprocesser

Automation & System

-

Applikationer med AMR & AGV

Applikationer med AMR & AGV

Automation & System

- Automatisering för låglyftande transport

- Automatisering för höglyftande transport

- Automatisering av smalgångslager

-

Automatiserad palltransport med AMR robotar

Automatiserad palltransport med AMR robotar

Applikationer med AMR & AGV

-

Automatiserad hantering av plastbackar

Automatiserad hantering av plastbackar

Applikationer med AMR & AGV

- Automatiserat lager (ASRS)

- Automatiserat lager för smådelar / Miniload

-

Pallsystem

Automation & System

-

Digitala Produkter och IT-System

Digitala Produkter och IT-System

Automation & System

-

Kundreferenser

Automation & System

-

Whitepapers

Automation & System

-

Lageroptimering & Rådgivning

-

Service & ReservdelarService & Reservdelar

Startsida | Jungheinrich Sverige

- Akuta serviceärenden

-

Beställ service via Call4Service

Service & Reservdelar

-

Servicepaket

Servicepaket

Service & Reservdelar

- Reservdelar & Tillbehör

-

Energiservice för truckar

Service & Reservdelar

-

Användarmanualer: Truckar & Ställage

Service & Reservdelar

-

AntOn by Jungheinrich Service

Service & Reservdelar

-

Kunskap & ReferenserKunskap & Referenser

Startsida | Jungheinrich Sverige

- Kundcase - Branschvis

-

Kundreferenser

Kunskap & Referenser

-

Blogg om intralogistik

Kunskap & Referenser

-

Hälsa & säkerhet

Hälsa & säkerhet

Kunskap & Referenser

-

E-mobility

Kunskap & Referenser

-

Hållbarhet

Kunskap & Referenser

-

Certifikat & Utmärkelser

Kunskap & Referenser

-

Användningsområden

-

Litiumjonteknik

Litiumjonteknik

Kunskap & Referenser

-

Innovationskraft - Kundfördelar

Kunskap & Referenser

-

Kontakt & Om ossKontakt & Om oss

Startsida | Jungheinrich Sverige

- Kontakta oss

-

Kontor och försäljning

-

Hitta närmaste kontor

Kontakt & Om oss

-

Vår historia

Kontakt & Om oss

- Karriär

-

Press/Evenemang

-

Samhällsengagemang | CSR

Kontakt & Om oss

-

Innovation och ambitioner

-

Webbshop